Best Ways to Use Your Floor Sweeper

Think about commercial sweepers like traditional sweeping brooms on steroids. The objective is exactly the same, however the speed and effectiveness of the process increases by a significant amount.

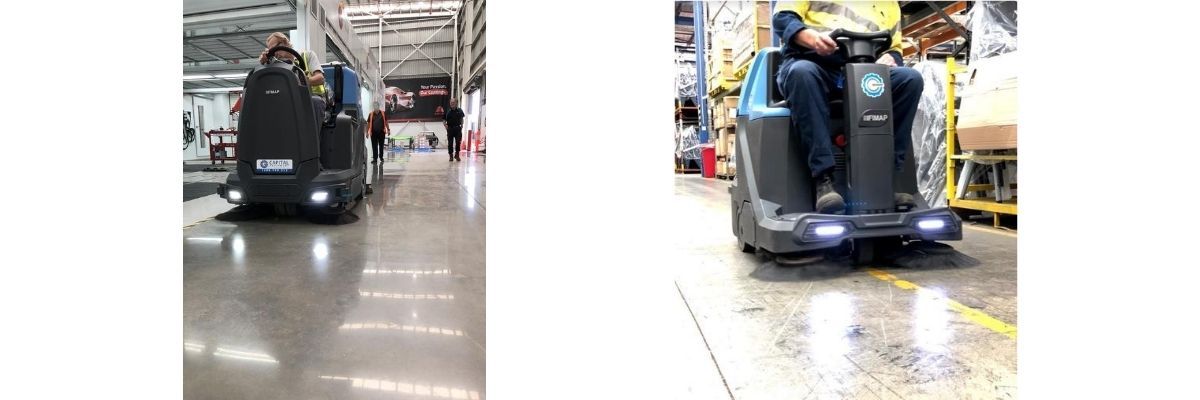

Sweeping is a dry method of cleaning that involves the collection of loose debris and litter including dust, particles and dirt loaded into a hopper/container for disposal. Using a walk behind floor sweeper or a ride on floor sweeper for regular facility maintenance increases facility safety, housekeeping efficiency, company image amongst customers, and staff morale by working in a clean and safe work environment. Commercial sweepers or industrial sweepers achieve better cleaning results than a team of cleaners with traditional sweeping brooms at a much faster rate, reducing labour costs.

Sweeping goes beyond just cleaning a floor, dust can have serious health implications from staff inhaling fine dust particles, so your sweeping activities need to be taken seriously with reliable, well maintained equipment to assist.

Here are 6 simple tips to sweep right:

- Understand your machine - Read. The. User. Manual.

- Choose the right type of brooms

- Empty the hopper & clean filter regularly

- Replace consumable parts when required

- Inspect & clear sweep path to avoid large & heavy objects

- Understand the different sweeping methods.

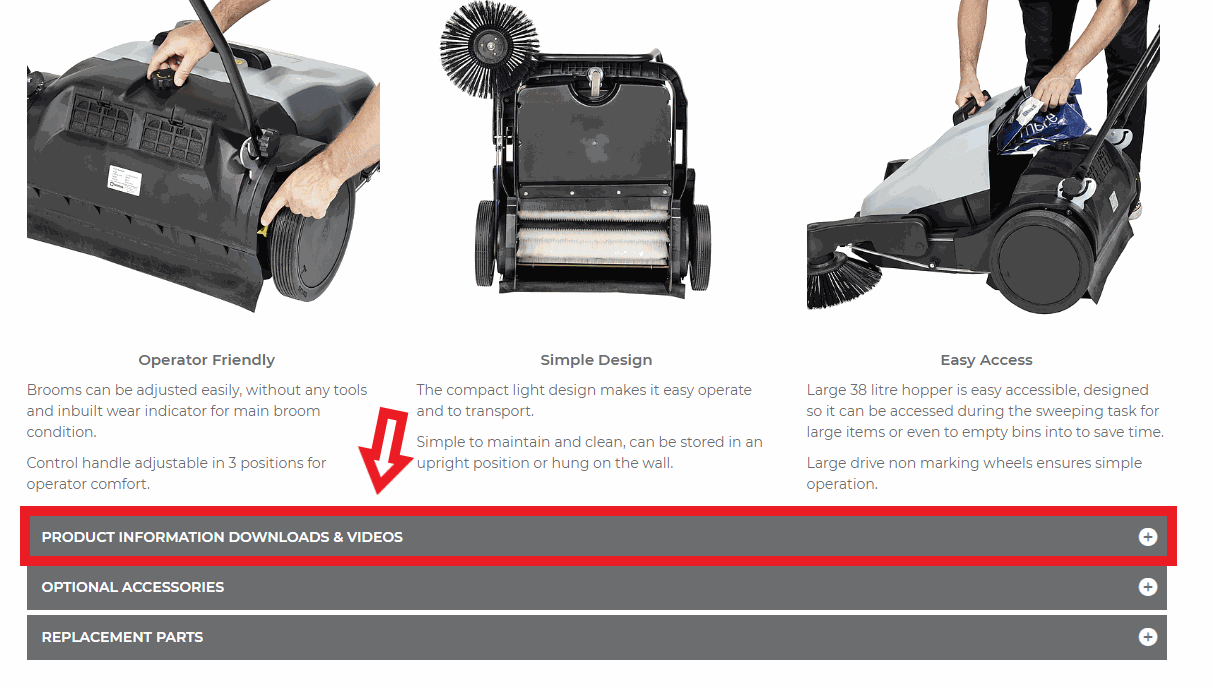

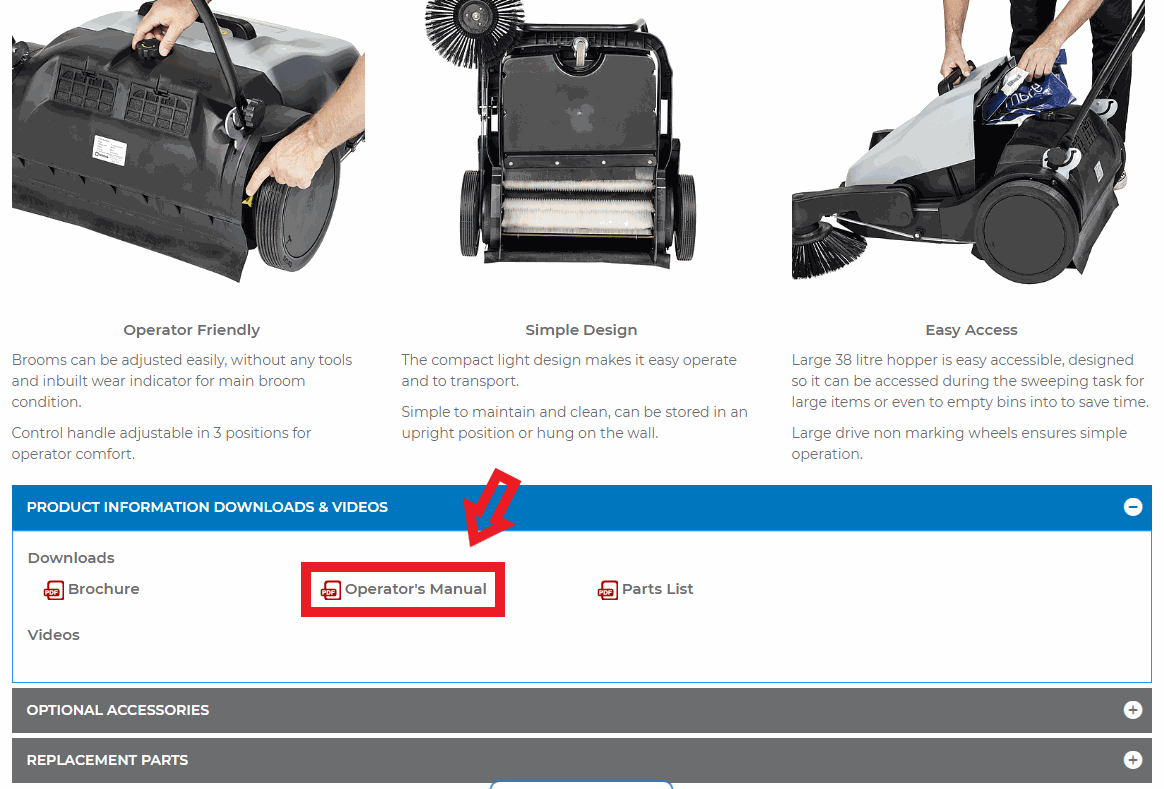

1. Read the user/operator manual

To make it easier, every machine on our website has it’s user manual attached to the product page for your convenience. If you cannot locate yours, please email parts@capitalequipment.com.au so we can provide a copy or advise where it can be sourced.

2. Choose the right type of brooms

Sweeping brooms are available in various designs, sizes and bristle material types which are designed for different applications. Ensure you fit the correct type of brooms for your site to gain the most performance from your machine.

Side Broom: Side brooms consist of bristles inserted on an angle around the circumference of a disc type base and are designed for edge cleaning by directing dust, litter and/or debris from the hard to reach areas towards the main broom for pick up. It is very important to have the side broom adjusted correctly for best edge sweeping performance, consult your user manual for more information. It is recommended to deactivate the side broom system once edge cleaning is complete to reduce wear and dust generated from the side broom and obtain uniform cleaning results.

Main Broom: Main brooms consist of bristles inserted in a spiral or chevron pattern around the circumference of a cylindrical core, designed to rotate and contact the width of the broom, sweeping the surface to collect dust and debris. The main broom is responsible for the majority of the machine's sweeping path, picking up litter and loading it into the hopper assembly. The main broom rotates within a vacuumised broom housing, fine dust and particles are directed and contained in the dust control filter (polyester/paper) by the vacuum system. The main broom offers greater sweeping performance than the side broom due to the broom design and main broom housing being vacuumised. Always overlap the main broom cleaning path when sweeping to gain a uniformed cleaning result.

Main brooms are available in full or half fill variants depending on the type of debris being swept. Please see our sweeper broom guide for a detailed outline.

3. Empty the hopper and clean filter regularly

The hopper inside floor sweepers is the container that litter, debris and dust is stored during the sweeping process. The size of the hopper varies from model to model, either a manual emptying process or raised hydraulically to dump into an industrial bin (reducing manual handling). The type and size of a sweeper’s hopper capacity should be considered during the decision process to ensure it is suitable for the typical type and size of debris found at the desired site.

Check the hopper capacity level regularly so it’s emptied when maximum capacity is reached prior to it affecting pick up performance. Hopper emptying and general cleaning should also be completed when finishing the cleaning task to reduce ongoing corrosion, odours. It also ensures it’s ready to use effectively in the next cleaning session.

Pick-up performance will be dramatically reduced when the hopper has reached maximum capacity and can cause your sweeper to work at a lower efficiency if build-up has occurred over time from lack of cleaning.

4. Replace consumable parts when required

Optimal sweeping performance requires brooms to be of good condition, over time these wear and require replacing to maintain effective sweeping performance. The most common consumable parts for sweeping machines are the brooms, which can be easily replaced by the operator with no tools for most floor sweeper models (but not all models). Depending on the adjustment pressure, broom type and application determines the life expectancy achieved. Refer to your manufacturer’s user manual which will indicate the broom length in mm that signifies when it has reached its serviceable life. A level of caution is needed when replacing side brooms as sharp pieces of debris can be stuck in the bristles, wearing gloves is recommended. It is important to ensure your brooms are adjusted correctly for optional sweeping performance, this adjustment may require resetting when installing new brooms, model specific. Please consult your user manual for information.

Optimal dust retention requires filters to be clean and in good condition, there are various types of filters and filter materials available to suit different applications. Popular material types are paper or polyester, as a general rule paper breathes better although can be damaged easily from moisture or from sweeping over wet areas. Polyester filters are more durable and are washable however some do not breathe as well when compared to paper types.

Panel filters are the standard filters fitted to most machines, whereas the pocket filters can be fitted as optional accessories for machines including the Fimap FSR. Pocket filters have better dust control due to the extra panels that make up the filter.

5. Inspect & clear sweep path to avoid large & heavy objects

Always do a walk-around to inspect the area prior to sweeping. Large items, oversized debris or foreign materials should be picked up before sweeping to clear the path to cover the area quickly and effectively. This also allows you to map out a sweeping plan for the desired area.

Industrial and commercial sweepers have limitations to the type of debris they can collect from floors. Bulky debris, including rocks, pieces of steel, shrink wrapping, and pallet debris, can cause blockages and damage to internal components of the machine. It is important not to sweep over lengths of shrink wrap, rope or packing tape as this will tangle around and damage your brooms and/or hydraulic/electric motors. Your user manual will provide specific debris warnings for your machine, so be aware of this before sweeping. Sweeping wet surfaces is also not recommended, but if you must, turn your dust control system off to eliminate moisture in the filter assembly.

6. Understand the different sweeping methods

Most modern sweepers are designed to collect litter in either a direct throw or over throw sweeping system. Identifying the most suitable sweeping method you require will help determine the right model type to purchase or hire.

Direct throw → For heavier debris.

Direct throw are machines that typically have the hopper located in front of the main broom. Debris is flicked forwards into the front hopper, preventing debris getting stuck in the main broom housing. Direct throw systems are efficient in sweeping heavy debris such as sand due to less travel distance it has to be loaded into the hopper. It is only possible to utilize approximately 60% of the hopper volume due to the forward filling direction debris is loaded into the hopper.

Commercial and industrial sweepers like this include: Nilfisk SW750, Nilfisk CS7010, Nilfisk SW8000.

Over throw → For lighter debris.

Over throw are machines that typically have the hopper located behind the main broom. A whirlwind effect is created by the mainbroom, flicking the debris over the broom into the rear hopper. Debris is loaded from the top of the hopper allowing it to utilise approximately 100% of the capacity, very effective for light material.

Industrial and commercial sweepers like this include: Nilfisk SW5500, Fimap FSR, and Nilfisk SW4000.

Before your head explodes with these simple, effective sweeping tips, always remember that if you have any questions left unanswered, our sales and parts team are more than happy to assist you so you gain the most from your machine and/or achieving effective cleaning solutions for your application.

.png?access_token=9afec6ad-24af-4e88-bae0-766fe70e7076)